About us

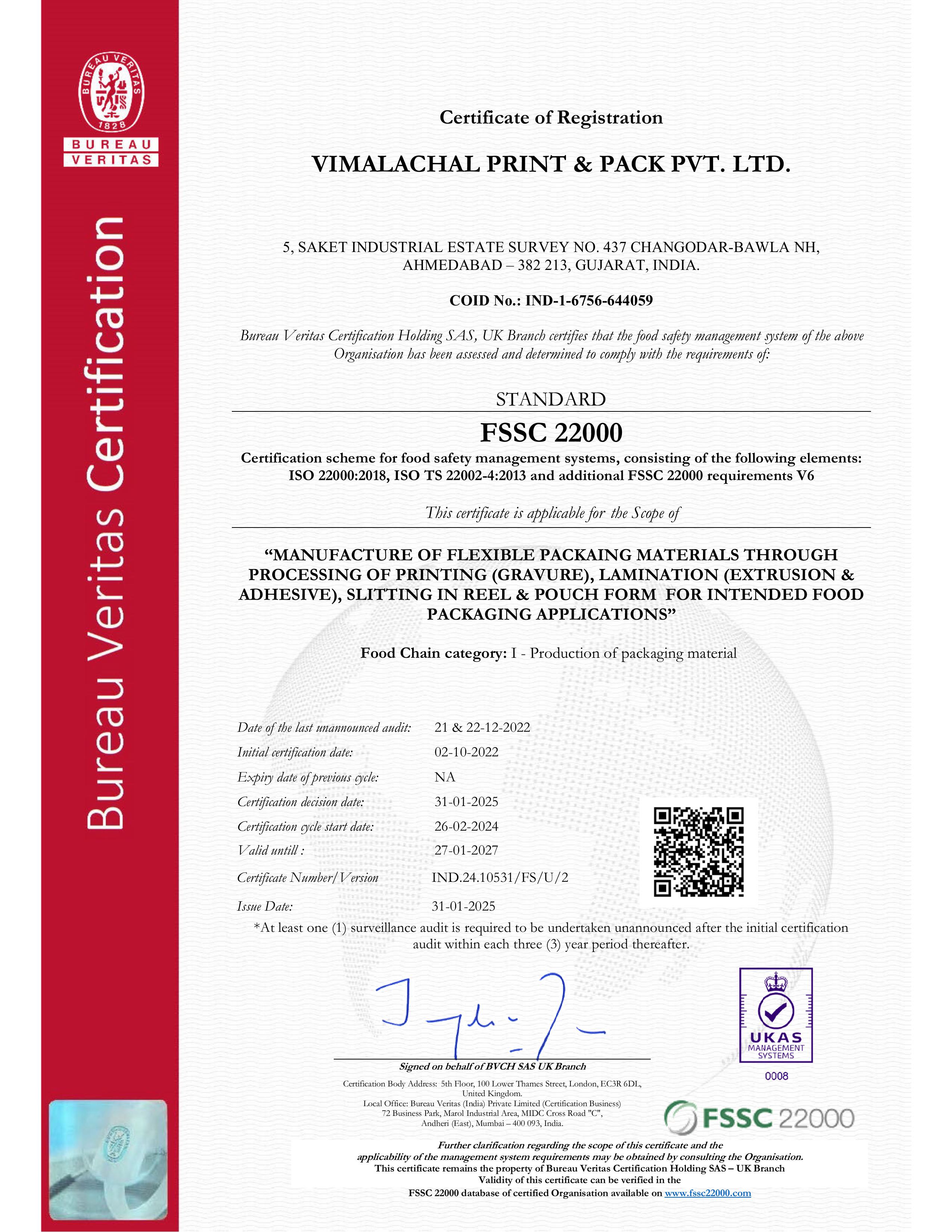

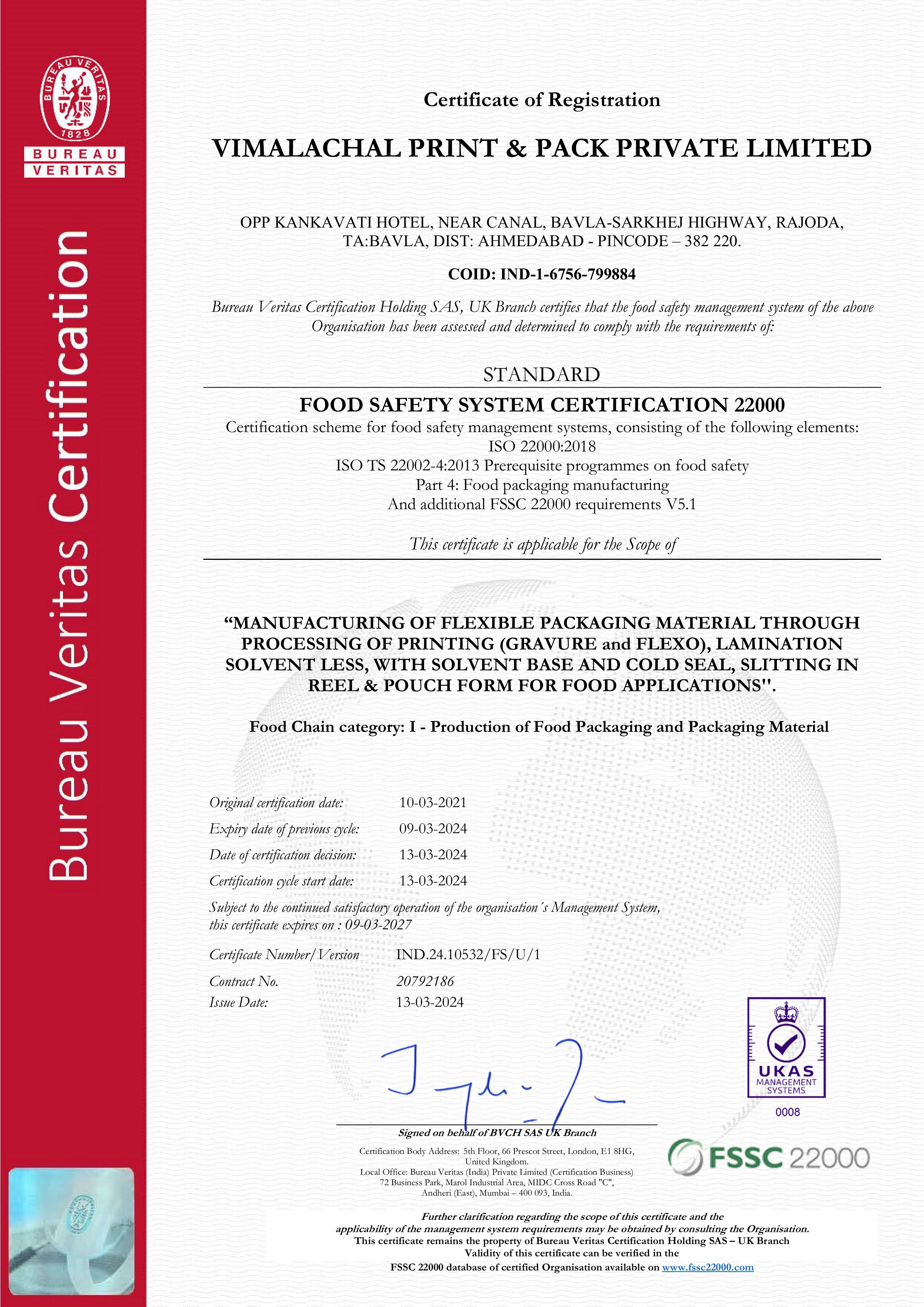

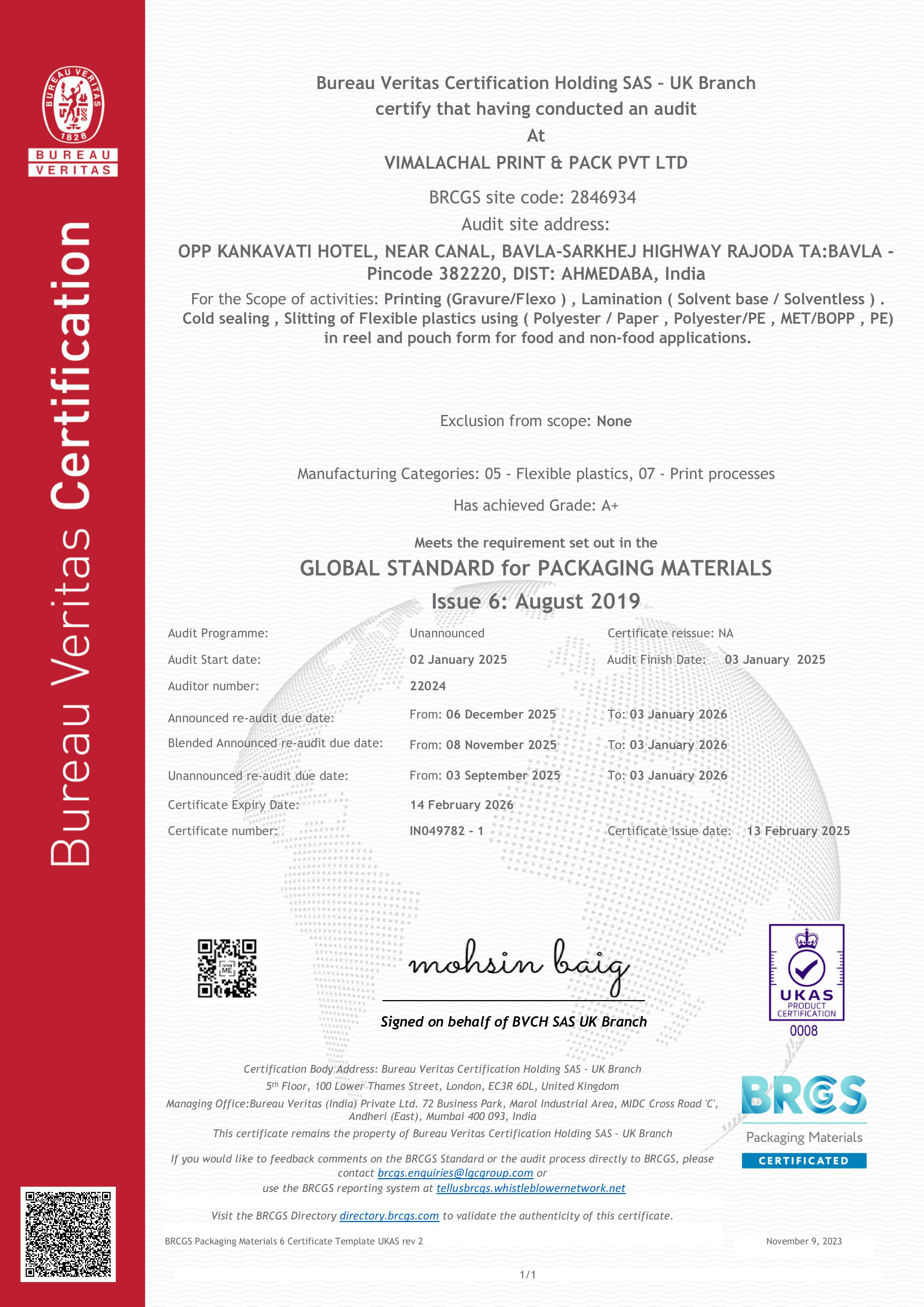

In 1989, Vppl had an idea to create a packaging unit. With its state-of-the-art flexo printing press, they were able to produce high-quality images with a wide range of colors. This allowed for custom designs to be quickly and efficiently produced. Vppl has been a leader in the flexo-packaging industry for 33 years. The company has built a reputation for innovation, quality, and customer service. Its experienced team of professionals provides the best possible customer service and helping customers achieve their packaging goals. We are committed to providing the highest quality products and services.